A Literature Review on the Proton Saga FLX Automative Relay Box Cover

Automotive relay box screen

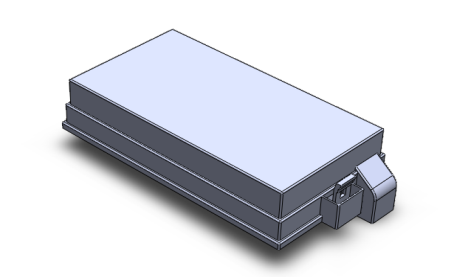

The merchandise chosen for this survey is relay box screen from Proton Saga FLX. A relay box screen are manufacture by utilizing injection modeling procedure. The map of this screen is to avoid the H2O from flow into the relay portion that located in goon of auto. Basically, the fictile portion of automotive usage plastic from thermosetting household. The polypropene ( PP ) stuff was choose to utilize in this undertaking.

Order custom essay A Literature Review on the Proton Saga FLX Automative Relay Box Cover with free plagiarism report

450+ experts on 30 subjects

450+ experts on 30 subjects

Starting from 3 hours delivery

Starting from 3 hours delivery

Figure 2.1: Automotive relay box screen

Material

Polymer is a larger category of stuff that consist many little molecule known as monomer. In make up one's minding to increase the quality in merchandise that produce in plastic industry, many manner is discover to increase the quality of merchandise. Type of fictile stuff is a 1 of solution in green goods a good quality so if take a incorrect stuff will do the quality of merchandise lessening.

Polypropylene [PP]

Harmonizing to Tripathi ( 2002 ) polypropene ( PP ) was found by G. Natta by following work from K. Zeigler by the polymerisation of propylene monomer in 1997. Polypropylene is manufactured by add-on polymerisation and in group of semi-crystalline thermoplastic. After last four decennary, polypropene is fictile stuff which is 3rd largest consumed after Polyethylene ( PE ) and Polyvinyl Chloride ( PVC ) .

Figure 2.2: Polypropylene (PP) construction.

Advantages of polypropene (PP):

- Low-cost technology plastics

- Good chemical opposition

- Good detergent opposition

- Good weariness opposition

- Higher opposition temperature

- Good hardness, stiffness, strength

Disadvantages of polypropene (PP) :

The chief applications of polypropene (PP) in different market sectors in table below:

| sector | Typical applications |

| Automotive industry | Radiator enlargement valve, battery instances, tool boxes, bumper screens, splash guards, maneuvering wheel screen, side strips |

| Family good | Video cassettes, baggage, bottle caps, nutrient processor lodging, bowls, pail, playthings |

| Domestic contraptions | Serve washer parts such as top frame, cellar, bath, extruded gaskets, H2O canal, etc.

Refrigerator parts such as boxes, containers, shortss, canal, recess and mercantile establishment pipe Microwave oven cabinet, chainss and java shaper organic structure parts |

| Electrical applications | Cable covering, overseas telegram yokes and antenna constituents |

Table 2.1: Polypropylene (PP) in different sector. Beginning: Tripathi (2002)

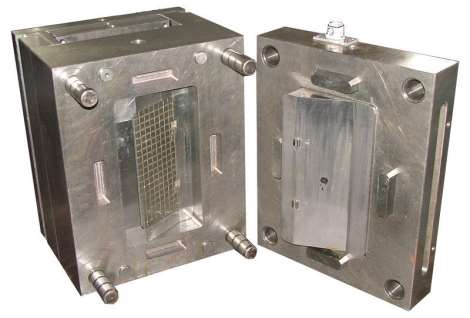

Injection Modeling

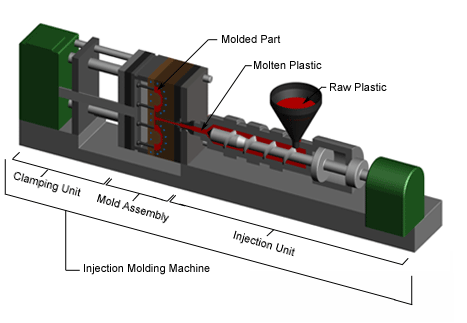

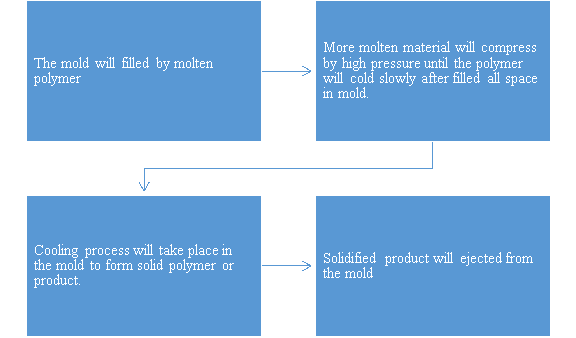

Nowadays Injection casting is one of largest used in fabricating procedure by utilizing thermo-polymer and thermoset as stuff for fiction. A assortment of merchandise are manufactured by utilizing injection casting procedure because of flexibleness of merchandise end product. There are some of our day-to-day used merchandise that industry from injection procedure. For illustration compact phonograph record, toys, car bumpers, nomadic phone lodgings and tiffin boxes. Harmonizing Shin and Park ( 2013 ) the procedure of green goods some merchandise is requires three things which is injection-molding machine, natural plastic as a stuff, and cast in ( figure 2.3 ) . Injection casting is a reiterating procedure or cyclic procedure. Harmonizing Kennedy ( 2008 ) Injection modeling consists of four chief phase to finish the procedure to bring forth some merchandise in ( figure 2.4 ) .

Figure 2.3: Injection modeling machine.

Figure 2.4: Four chief phase in injection casting procedure.

Gate

Gate placement is a chief of successful of injection modeling procedure. Gate is a like a valve for liquefied polymer through to the cast. The map of gate is really of import in injection modeling procedure to acquire a good quality of merchandise. Gate should be located at country that have less use emphasis in portion and at where decorative non really concern. If we choose a incorrect gate location the merchandise will do low quality and besides the defect will happen on the merchandise. The proper gate location can maximise quality of merchandise besides it can avoid defect to happen. Harmonizing Beaumont ( 2006 ) for gate locate at margin in a cast, more prefer use two-plate cold smuggler system. In extra, three-plate smuggler system can be used on gate that locate at inside margin.

Thickness of portion is one of job in make up one's minding location of gate. Normally merchandise have fluctuations in thickness which is thin and thick portion in one merchandise. The gate must be locate at thick portion foremost compare to thin portion. This will minimise existing of defect in merchandise such as sink and nothingness at thick part and besides uncontrolled of shrinking job. During make fulling procedure the thin portion will freeze-off anterior comparison thick portion. Logically, more force per unit area must be supplied to come in the cast if gate locate at thin portion and besides chance all pit to thick portion will be blocked because of flow of melt plastic already freeze. This will ensue shrinking at thick portion besides voids, sinks, and emphasis. The bing residue emphasis will take to warpage job in fictile portion.

The location gate chosen must be in this standard Beaumont (2006) :

- Gate must be locate at thickest portion or subdivision (To avoid sinks, shrinking, warpage and nothingness)

- To guarantee unvarying filling and packing gate must turn up at balance flow way

- See weld line on critical subdivision

- Locate at ease topographic point or subdivision for degating procedure

- The gate grade should non desert the visual aspect of merchandise

- Gate location will supply a type of gate will used

- Focus on length of flow through cast (to guarantee adequate force per unit area to make full cast)

- Know the maximal value force per unit area of clinch tonnage/mold can be covered

The size of gate besides must be concern to acquire a good quality of merchandise. Gate size must be start by smaller size foremost and increase the size until a proper wadding in pit cast bend to constant. The form of merchandise besides ensuing in choice of where gate will turn up for better quality. For 3-dimensional form ( box or cup ) more prefer gate locate at centroid of cast. This will ensue the radial flow form on portion and the filling procedure more easier besides low defect will be. In the (table 2.2) below show recommended forms and location of gate.

| characteristic | |

| Gambar dalam buku how to do injection casting

Tgk Defense Intelligence Agency punya ayat balik |

Centric gate

|

Bizarre gate

|

Table 2.2: Recommended forms and location of gate. Beginning: How To Make Injection Molds-Menges and Mohren (1993)

Some merchandise will confront blush grade because of portion of the frozen tegument flow with melt plastic into pit during injection procedure. After the unwanted stuff jet into pit it will do gushing this stuff non remelt in the stuff that jet into pit. Beaumont (2006) said that gushing go on because of high speed from restrictive gate jet the stuff that non yet melt. To get the better of this job by follow the guideline for gate design feature in the (table 2.3) below Menges and Mohren (1993) .

| Gate design | Characteristic |

| Gambar

Tukar ayat sekali |

Gate should be positioned in such manner that no jetting can happen doing troublesome grade ; melt must encroach in wall or other obstruction

If gate is machined merely into one cast half, cold “skin” may be carried into pit. This besides consequence in bloom Markss. Redress: a particular cold bullet good accepts cold stuff. |

| Centric location of gate with disconnected passage and rough walls prevent conveyance of cold surface bed.

Radius at passage causes laminar flow of thaw into pit and prevent jetting. |

Table 2.3: Guideline for gate design characteristic. Beginning: How To Make Injection Molds-Menges and Mohren (1993)

The optimal size of gate depend on:

- Mold temperature

- Melt temperature

- Volume stuff to be injected into the feeling

- Modeling wall subdivision

- The flow feature of the stuff to be mold.

Type of gate

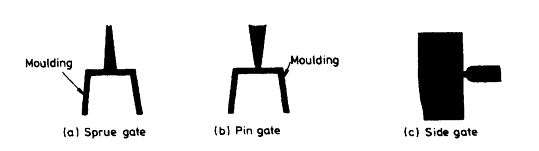

The chief intent of gate is to link smuggler to model pit during injection procedure. So gate have many type to carry through a different cast to accomplish a good form and quality of merchandise. Basically, there are three common type of gate that normally used in injection casting procedure Crawford ( 1998 ) :

- Sprue gate

- Pin gate

- Side gate

Figure 2.5: Three common type of gate normally used. Beginning: Plastic Engineering by Roy J. Crawford (1998)

Cast

Cast can be defined as a portion that act as to determine fictile stuffs. The major map cast to reassign as topographic point that melt plastic will reassign into cast to organize a coveted form and chuck out when thaw plastic bend to solid. Mold consist of nucleus and pit. Basically the pit side is a side that melt plastic will flux to cavity side from nose. Core side maps as defining and besides as expulsion system after melt fictile solidify.

Single pit cast

Process production of big portion normally differ with little portion in injection casting. Rees and Catoen ( 2006 ) said that big portion are molded utilizing individual pit cast. The production of larger portion are frequently non required in a larger measure. In extra, the building of individual pit cast usage simplest building with a simple injection method and simplest expulsion portion.

Figure: Single pit cast.

- Two home base cast

- Three home base cast

Variables in injection casting

There some of variable that will play importance function in happening of optimal parametric quantity in injection casting procedure. The value of this parametric quantity will impact the quality of merchandise if non to the full function decently. Harmonizing to Rosato (2000) incorrect input of parametric quantity puting will take to quality of merchandise bad besides the preciseness will diminish besides will increasing the cost and clip of production.

Four type of variables will used in injection casting procedure:

- The injection force per unit area

- The wadding force per unit area

- The mold temperature

- The thaw temperature

Injection force per unit area

The injection force per unit area is a most of import parametric quantity in successfully present a thaw plastic to whole mould portion. The thaw plastic is force through the nose and present to model infinite. The job during bringing of thaw plastic, the stuff fast cooled if contact with mould surface will traveling and it causes defect if fictile non filled decently with adequate force per unit area. If force per unit area low the thaw plastic non fulfilled mould infinite and high force per unit area besides can do overpacking on merchandise.

Packing force per unit area

Packing force per unit area is a force per unit area that map to avoid a thaw plastic flow back out of mold infinite during injection modeling procedure. Packing force per unit area besides act as secondary force per unit area phase.

Mold temperature

Mold temperature is one of of import to see in during injection modeling procedure. Temperature of cast are of import in concluding portion that required surface of merchandise smooth and in good status. If mold temperature low, it will do melt fictile hard to make full besides lead to increasing of injection force per unit area. The cast with higher temperature will cut down emphasis in cast while make fulling procedure and the surface coating will better.

Melt temperature

Melt temperature known as temperature of fictile stuff to run before injection procedure. A to Higher temperature will do polymer will alter their belongingss. Melt temperature will consequence on the viscousness of thaw plastic that will through mold infinite by bringing system.

| Parameter | Value |

| Injection force per unit area | 100-130 MPa |

| Packing force per unit area | |

| Mold temperature | 15-65OC |

| Melt temperature | 230-275OC |

Table 2.4: Parameter of injection casting for polypropene (PP). Beginning: Rees and Catoen-Selecting Injection Molds (2006)

Defect

Plastic injection casting is an effectual industry in production of plastic. In industry universe, the merchandise green goods are non in one hundred per centum ( 100 % ) in good quality production. Even in injection casting procedure besides have a same job in quality of merchandise based on defect occurred.

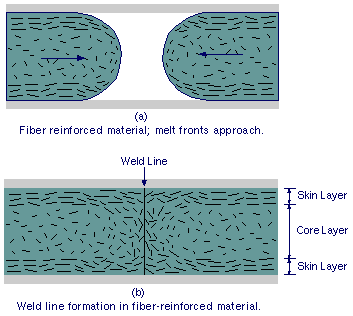

Weld line

Weld line normally occur during the mold filling procedure when thaw plastic flow in mold form and recombined at terminal of pit or downstream location. The surface of merchandise will look like cleft of the shaped portion and if many weld line exist in merchandise it will considered low quality merchandise. The presence of weld line ever occur in plastic cast production and it will failure the merchandise if used in structural applications due to diminishing strength at weld country.

Weld line can split into two ( 2 ) types which is butt dyer's rocket and meld dyer's rocket. Butt weld occurred when thaw plastic going with antonyms way and meet. Other weld line exist when involve extra flow when thaw plastic have recombined in mold pit. This dyer's rocket called meld dyer's rocket. But most normally exist dyer's rocket is butt dyer's rocket because it cause most jobs.

Figure: formation of weld line. Beginning: Santa Clara University - Engineering Design Center (2006)

Gambar butt dyer's rocket and canasta line

Harmonizing Malloy (2010) the weld line exist can be overcome by consider in procedure:

- Increase thaw and cast temperature

- Increase velocity of injection

- Increase clip and retention force per unit area

- Mold design must be recheck

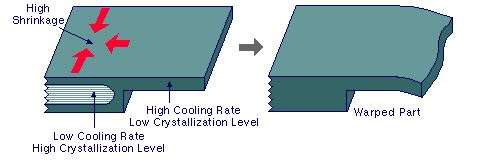

Shrinkage

Shrinking occurred during chilling clip. Shrinking happen when thaw plastic flow in cast that indirect contact with cold cast. Harmonizing Beaumont ( 2006 ) shrinking have many job and it may impact the warpage, residue emphasis and portion size. In other words, shrinking is a volume decreases as plastic cools and solidified. Pressure of expulsion to take portion from nucleus of cast will increase because of shrinking because alteration in form or warpage.

Figure: Shrinking exist at thick portion lead to warpage job. ( Beginning: Santa Clara University - Engineering Design Center (2006)

Malloy (2010) said shrinking can be avoid by:

- Keeping force per unit area must high plenty but low plenty to avoid of over packing go on that can take to high degree residue emphasis

- Preferable gate at thickest subdivision foremost compare to thin because it enable packing at thick subdivision. Thick portion hard to chill and pack because its return longer clip to chill

From Beaumont (2006), the shrinking can be observe by utilizing different type of stuff and it’s for mention intent merely in considered shrinking defect. Table 2.5 below shows the type of polymer shrink way flow and it mean shrinkage value.

| Material | Thickness consequence induces shrinking | Average additive shrinking | |

| midst ( 3mm + ) | thin ( & lt ; 3mm ) | ||

| Acrylonitrile-butadiene-styrene | isotropic | parallel* | 0.0043 |

| Personal computer | isotropic | parallel* | 0.0057 |

| PS | parallel* | parallel** | 0.0035 |

| Polyvinyl chloride | perpendicular* | perpendicular* | 0.0044 |

| HDPE | parallel* | parallel** | 0.0234 |

| PP | isotropic | parallel* | 0.0133 |

| NYLON 66 | perpendicular* | parallel** | 0.0162 |

| Definitions: Parallel- polymer shrivel more analogues to way of flow

Perpendicular- polymer shrivel more perpendicular to way of flow Isotropic- additive shrinking independent of flow way *Low degree of orientation consequence **Medium degree of orientation consequence ***High degree of orientation consequence |

Table 2.5: Type of polymer shrink way flow and mean shrinking value. Beginning: Beaumont (2006)

Sink grade

Sink grade are imperfectnesss of the merchandise that exist during injection procedure. Rees and Catoen ( 2006 ) said that during injection procedure, hot plastic through the thick portion in cold cast wall. The thaw plastic to the wall and solidify foremost while melt plastic fluxing in cast. This causes melt fictile hard to finish fill in pit and causes of bing sink grade. Sink mark expression like a little hole or depressions. Normally appear at intersections of rib and wall or at thickest subdivision.

Figure: Sink mark exist on plastic. ( Beginning: hypertext transfer protocol: //www.reblingplastics.com/quality.htm )

The option to get the better of:

- Increase injection force per unit area

- Increase cast temperature

- Reduce injection velocity

- Air trap

After injection procedure, the thaw plastic will get down excessively solidified in the cast. The air occurred during chilling phase because of air trapped in liquefied plastics. This will make an empty infinite within the portion and consequence the quality of merchandise. The solution to get the better of this job by increased the keeping force per unit area.

References

- DRM Associates, 2007.Injection Moulding Glossary. [ on-line ] Available at: & lt ; hypertext transfer protocol: //www.npd-solutions.com/injectmouldglos.html & gt ; [ Accessed 5 September 2010 ]

- P. K. Kennedy,Practical and Scientific Aspects of Injection Molding Simulation, chapter 2, Technische Universities Eindhoven, Eindhoven, The Netherlands, 2008

- M.C. Huang and C.C. Tai, “The effectual factors in the warpage job of an injection-molded portion with a thin shell feature” ,J. Mat. Proc. Tech., vol. 110, 2001, pp. 1–9. D.V. Rosato, M.G. Rosato, “Injection casting handbook”Massachusetts: Kluwer Academic Publishers, 2000.

- hypertext transfer protocol: //www.sabic-ip.com/gep/Plastics/en/ProductsAndServices/ProcessingUsingIMDDetail/mold_temperature.html

- hypertext transfer protocol: //mould-technology.blogspot.com/2007/12/injection-molds-classification.html

- hypertext transfer protocol: //books.google.com.my/books? hl=en & A ; lr= & A ; id=nxYuCCGQ7Z0C & A ; oi=fnd & A ; pg=PP2 & A ; dq=Crawford, +R. , +1998.+Plastic+Engineering, +3rd+ed.+Oxford: +Butterworth+ % E2 % 80 % 93+Heinemann & A ; ots=ZtSIW48je8 & A ; sig=sKQ9yVYTxsXYqQ2cS -- ohC4Pq_g # v=onepage & A ; q=type % 20of % 20gate % 20 & A ; f=false ( roy j. Crawford )

- hypertext transfer protocol: //www.dc.engr.scu.edu/cmdoc/dg_doc/develop/process/physics/b3500001.htm

- hypertext transfer protocol: //www.reblingplastics.com/quality.htm

- hypertext transfer protocol: //www.dc.engr.scu.edu/cmdoc/dg_doc/develop/trouble/weldmeld/f6000001.htm

Cite this Page

A Literature Review on the Proton Saga FLX Automative Relay Box Cover. (2018, Aug 10). Retrieved from https://phdessay.com/a-literature-review-on-the-proton-saga-flx-automative-relay-box-cover/

Run a free check or have your essay done for you