Six Sigma Methodology – DMAIC

Introduction to Six Sigma

In the current scenario of planetary competition, the quality, abilities and cognition gives a competitory border to an administration over other administration. It is now an cosmopolitan truth that the end sheet of an administration comprises of end to go universe category maker. Six Sigma methodological analysis is renowned to accomplish these above mentioned ends. The administration that has potency to acquire clients delighted by supplying good quality merchandises and services has the possible to rule over other administrations ( Snee RD, 2004 ) . Harmonizing to General Electric CEO Jack Welch, Six Sigma is “the most ambitious and potentially rewarding enterprise we have of all time undertaken” ( Breyfogle, 1999 ) . The initial flicker of Six Sigma started in fabrication industries and hints of its application can be traced out in fiscal services, health care ( Snee, 2003 ) .

The Six Sigma attack is a systematic attack which follows a predefined tract to better the procedure capableness. Six Sigma methodological analysis is a statistically based attack to minimise fluctuation therefore cut downing defects. Statistical representation of Six Sigma shows the spread of the procedure over a predefined graduated table demoing how good a procedure is executing. Six Sigma methodological analysis focuses on “processes” . Expected result of a procedure has a step called “Mean” . Expected result of a procedure has some fluctuation in it. Sigma degree is step of that fluctuation ( Kaushik, et.al. , 2008 ) . It is deserving observing that Six Sigma has got some fuel left in it and it is still constructing impulse with any mark of allowing up ( Hoerl, 2004 ) .

Order custom essay Six Sigma Methodology – DMAIC with free plagiarism report

450+ experts on 30 subjects

450+ experts on 30 subjects

Starting from 3 hours delivery

Starting from 3 hours delivery

Six Sigma novices as a concern scheme and ends with top-down execution, ensuing in impact on net incomes if successfully implemented ( Salzmen et.al. , 2002 ) . Six Sigma purpose is to accomplish 3.4 defects per million chances ( DPMO ) with merely one premise i.e. the procedure average displacement by every bit much as 1.5 standard divergences off the mark ( Walters, 2005 ) . A individual defect chance is a procedure failure that consequences in critical to quality issue to client ( Linderman et.al. , 2003 ) . Harmonizing to Voelkel et.al. , ( 2002 ) , Six Sigma blends right direction, fiscal and methodological elements to do betterment in procedure every bit good as merchandises. Harmonizing to Tomkins ( 1997 ) , Six Sigma is a plan aimed at the close riddance of defects from every merchandise, procedure and dealing.

Sig Sigma provides a tract to implement cultural alteration throughout the administration. Large companies are happening six sigma methodological analysis utile in development of corporate concern programs. Business program developed utilizing this methodological analysis rules will take to single undertakings to better the person processes which will hold impact for the company. Both facets acts as a accelerator for cultural alteration and will reflect an individual’s attempts straight over the corporate aims.

Six Sigma is a information driven and structured programme that works at a company’s foundation to steer its manner towards making operational excellence ( Darshak, 2008 ) . Six Sigma is an integrating of statistical thought and statistical technology into an bing system of technology application ( Shung et.al. 2012 ) .

THE SIX SIGMA METHODOLOGY

Six Sigma is based on DMAIC methodological analysis which is an acronym for Define, Measure, Analyze, Improve and Control, it contains a systematic attack to look into the procedure from get downing to coating of the procedure. Six Sigma is a systematic application to better procedure by using the power of different statistical tools which measures the procedures and analyses them to cut down the fluctuation from end product of that procedure ( Gaddam et. al. , 2005 ) .

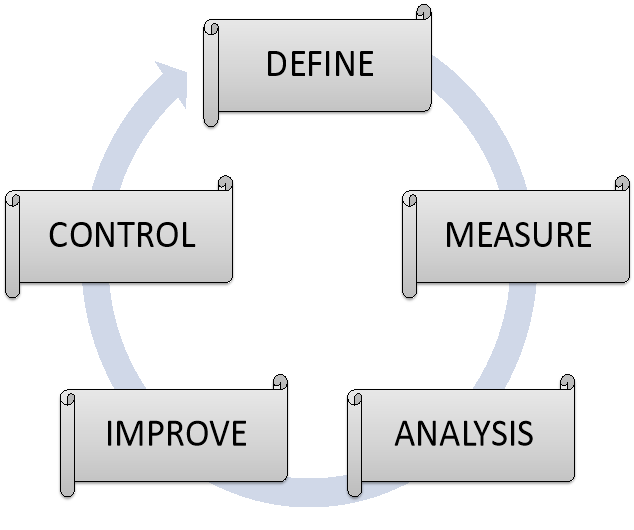

DMAIC comprises of five stages with each stage holding its ain set of tools and deliverables. These five stages are shown in figure 1. The cardinal procedures and cardinal tools that are used in these five stages are shown in table 1.

Figure1: DMAIC procedure

The Six Sigma practicians assess procedure public presentation utilizing Defects per million chances ( DPMO ) and sigma degree. The Six Sigma is a powerful concern scheme due to the tools used in this are holding direct linkage to concern aims and precedences. If the methodological analysis used is non robust plenty, the solution obtained will non be right and there is a possibility that the job will demo its root once more sooner or later ( Kaushik et. al. , 2008 ) .

|

Phase |

KEY TOOLS |

KEY PROCESSES |

|

DEFINE |

Undertaking Charter Pareto Chart Procedure flow diagram SIPOC diagram |

Specify the squad Team charter Brainstorming Specify the demands and outlooks of the client Specify the undertaking boundaries |

|

Measure |

Gauge R & A ; R Statistical procedure control |

Develop a information aggregation program Collect and compare informations Measure the procedure to fulfill customer’s need |

|

ANALYZE |

Fishbone diagram Process capableness analysis Hypothesis trials Arrested development analysis Failure manner & A ; effects analysis |

Determine the fluctuation in the procedure Analyze the fishbone diagram Choice of right hypothesis Prioritize chances for future betterment |

|

IMPROVE |

Design of experiment Confirmation and proof surveies |

Develop originative options Better the procedure to extinguish fluctuations |

|

Control |

Control charts |

Develop a program to supervise and command the improved procedure Control procedure fluctuations |

Table 1: DMAIC key tools and procedures

We can besides do a procedure flow diagram for execution of Six Sigma methodological analysis as it is a procedure in itself. The procedure flow diagram of Six Sigma methodological analysis is shown in figure 2.

Figure 2: Procedure flow diagram of Six Sigma methodological analysis

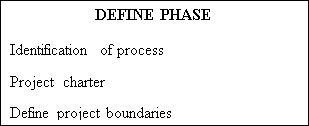

DEFINE PHASE

The chief aim of Define stage of DMAIC is to descry the undertaking chance and to formalize that it possesses a breakthrough potency. It is desirable that the undertaking or procedure selected be of import to both client and concern. If the administration has developed its ain concern schemes, the job should be under any of the schemes. Different degree of administration has their set of ends to accomplish. At the managerial degree or top direction degree, the end is to accomplish high return on investing. At the operations degree, end might be to increase the production of the procedure. At the undertaking degree, ends might be to increase the productiveness by cut downing defect degree.

One of the first points that sparks the induction of define stage is project charter. This is a papers that contains all the description of the undertaking i.e. range, start and finish day of the months, possible benefits to client, possible fiscal benefits to administration, squad members and their functions, and inside informations of any extra resources that will be utile during the undertaking. The charter should besides turn to the customer’s critical-to-quality features ( CTQs ) that are impacted by the undertaking. The job statement of the undertaking should depict the symptoms of the job non the antecedently known solution or possible causes. The squad should hold sufficient sum of members in it depending upon the undertaking. Each member must make his ain work within the clip provided for that work in the undertaking charter.

Use of graphical tools is done in define stage ; some of the commonly used tools include pareto chart, histogram, pie chart, procedure flow diagram ( PFDs ) , value watercourse function ( VSM ) and SIPOC ( Supplier/Input/Process/Output/Customer ) diagrams. These tools provide ocular item and AIDSs in understanding about what needs to be changed in the procedure.

The squad will necessitate to fix an action program for the following stage of DMAIC i.e. Measure stage. This readying must include single work assignments and probationary completion day of the months for the following stage. Before traveling to following stage, the squad demand to fix a reappraisal points on which reappraisal would be done. These reappraisal points must go to to these undermentioned:

- Does the job statement focal point on symptoms of the job?

- Does job statement contain possible causes or solutions?

- Does the undertaking has sufficient sum of fiscal impact?

- Have any obstructions come so far in the manner?

- A high degree SIPOC map completed or non?

- A procedure flow diagram completed or non?

- Proper justification made for undertaking choice or non?

- Is the team’s action program for Measure stage of DMAIC realistic?

MEASURE PHASE

The chief aim of Measure stage of DMAIC is to measure the current province of procedure. All the informations needed during the undertaking is collected in this stage on steps of quality, cost and rejection of the procedure. It is of import to make the listing of procedure input variables and procedure end product variables. Process input variables and procedure end product variables must be carefully defined and measured during the Measure stage.

One of the of import undertakings is to make up one's mind what and how much sufficient informations is needed to make thorough analysis and apprehension of current procedure. There is pick for informations aggregation i.e. historical informations and current informations. Sometimes the historical information may be deficient as the history can be uncomplete, methods for record maintaining alterations from clip to clip. The current information is holding the same system that is followed today and demand to be rectified. We can besides state the optimal method for informations aggregation is partly from historical informations and partly from current informations.

Problem can be selected through historical informations and now farther current informations can be used for informations fiting and analysis. From Gauge R & A ; R survey, the per centum fluctuation for the procedure can be calculated. CTQs of the procedure are identified so that it will be easy to concentrate Six Sigma on countries that will take to greater client satisfaction. In this we have to set up valid and dependable prosodies to assist monitoring advancement towards the defined ends.

At the terminal of Measure stage, the squad should update the undertaking charter if required, re-examine the ends and re-evaluate squad. The squad should include new members if they will be valuable in following stages of DMAIC. The squad can besides do few speedy wins extinguishing some non value added stairss in the procedure.

The squad will necessitate to fix an action program for the following stage of DMAIC i.e. Analyze stage. Before traveling to following stage, the squad demand to fix a reappraisal points on which reappraisal would be done. These reappraisal points must go to to these undermentioned:

- Are CTQ features identified?

- Does Process input and end product variables are listed?

- Procedure capableness must be documented.

- Any premises, if any must be documented.

- Performance criterions defined or non?

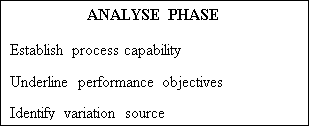

ANALYZE PHASE

The chief aim of Analyze stage of DMAIC is to reason the likely causes of the quality jobs, defects, rhythm clip. It is of import to sort causes in two ways i.e. common causes and conveyable causes. Removal of common cause is done by agencies of altering the procedure and remotion of conveyable cause is done by agencies of riddance of a specific job. The stage begins with benchmarking merchandise public presentation against the best-in-class so that new marks can be set.

In analyze stage, statistical tools every bit good as conventional quality techniques like brainstorming, fishbone diagram, root cause analysis, hypothesis testing, procedure capableness analysis, design of experiment ( DOE ) , arrested development analysis, two sample t trial, one sample t trial, failure manners and consequence analysis ( FMEA ) , graphical tools may be used for transporting out analysis. Process capableness analysis is done to mensurate the sigma degree and defects per million chances ( DPMO ) . One can easy happen out the available sum of chances for betterment in the procedure.

These Analyze tools are used for both type of informations collected i.e. historical and current informations in the Measure stage. These informations provides hints about the possible causes of the job. These hints have the possible to take to breakthroughs and place precise betterments. Analyze stage is rather of import in Six Sigma methodological analysis as its purpose is to place what causes the defects in each bomber procedure so that they can be modified and hence rectification of procedure can take topographic point either by redesigning the merchandise or re-engineering the procedure. It besides finds out if there is any probationary relationship between and among process variables. A list of causes that will be targeted in Improve stage should be listed down.

While making the toll gate reappraisal for Analyze stage, following points must be checked:

- Is the undertaking on path with regard to results and clip?

- Do we make to the root cause?

- What opportunities should be addressed during Improve stage?

- The analysis done is right or non.

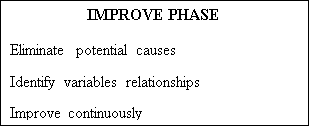

IMPROVE PHASE

The chief aims of Improve stage of DMAIC are to develop a solution for the job by riddance of root causes that are listed in analyze stage. A pilot trial tally is done after execution of solution. The pilot trial is kind of a verification experiment i.e. it evaluates the solution, paperss it and confirms the attainment of undertaking ends.

In Measure and Analyze stages, the squad selects procedure input variables and procedure end product variables, determines what information to roll up, how to analyse the informations and find how to construe the information. During the Improve stage, the squad make brainstorming Sessionss to make the particular changes that can be made in the procedure.

A assortment of tools can be used during the Improve stage. Use of value watercourse maps can be done to minimise the constrictions of the procedure and redesigning of the procedure to better procedure flow. Mistake proofing or poka-yoke can be besides implemented in some instances. Designed experiment is the statistical tool which is used in this stage.

An optimized solution is selected from these tools which can be implemented to the procedure. Desired consequence can be achieve by choosing the best alternate solution and implementing to extinguish the cause of the job. Improvements can be done in signifier of new procedure, developing to employees, equipments.

The toll gate reappraisal should affect following points:

- Proper certification should be at that place in support of job solution.

- Proper certification of all the alternate solutions that were considered.

- Documentation of analysis of the pilot trial tally.

- Plans to full scale execution of the solution.

- Any demand for developing to individuals, legal issues, impact on other concern activities.

- Analysis for hazards involved with the execution.

CONTROL PHASE

The aims of Control stage of DMAIC are to sum up all staying work of undertaking and manus over the necessary paperss of procedure betterment to procedure proprietor so that the additions from the undertaking will be sustained. Further horizontal deployment of undertaking is done to better similar processs. Documents should include all the inside informations of undertaking, updated operations, developing paperss and modified procedure map. Quantification of undertaking financials must be done.

After successful changing the procedure, monitoring is following most of import thing to be done to command the procedure. There should be a monitoring system for the solution under procedure control program. The of import tools that are used during Control stage are control charts, control program, poka yoke. Control charts are the largely used statistical tool in the Control stage of DMAIC. The procedure control program must include how to react to unforeseen failures in the hereafter. Sometimes poka yoke technique is used to guarantee complete remotion of the job.

The undertaking is so submitted to a reexamining commission that is formed in all the administrations to look into whether the squad has done a singular work or non. This is done for administrations internal awarding system. The commission will look into the originality of the paperss and undertaking. The list of paperss that should be attached are:

- Undertaking charter

- Project induction signifier

- Project entry signifier

- Undertaking financials

- Project one beeper

- Undertaking presentation

A toll gate reappraisal must be done including following points to:

- Undertaking ends achieved or non?

- Is the procedure control program complete or pending?

- Is all the certification for the undertaking complete?

- If any lesson learnt from the undertaking?

- Any range of horizontal deployment?

Cite this Page

Six Sigma Methodology – DMAIC. (2018, Aug 28). Retrieved from https://phdessay.com/six-sigma-methodology-dmaic/

Run a free check or have your essay done for you